Laser Book 247 Login

Laser Book 247 Login – Open Access Policy Institutional Open Access Program Guidelines for Special Topics Editorial Process Research and Publishing Ethics Article Processing Acknowledgments Awards Testimonials

All of his published articles are immediately available worldwide under an open access license. No specific permission is required to reuse all or part of an article published by , including figures and tables. For articles published under the Creative Common CC BI Open Access License, any part of the article may be reused without permission as long as the original article is clearly cited. For more information see https:///openaccess.

Laser Book 247 Login

Lead articles represent the most advanced research with significant potential for major impact in the field. The feature should be a large original article that incorporates several techniques or approaches, provides perspective for future research directions, and describes potential research applications.

Photonics & Lasers In Medicine

Main articles are submitted at the individual invitation or recommendation of scientific editors and must receive positive feedback from reviewers.

Editors’ Choice articles are based on recommendations from scientific journal editors from around the world. The editors select a small number of recently published articles in the journal that they feel are of particular interest to readers or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

By Jee-Eun Young 1, 2, Woosung Kim 1, Ji-Hyun Sung 1, Young-Joo Kim 3, Sung-Hyuk Park 2 and Da-Hie Kim 1, *

Received: August 5, 2022 / Revised: August 25, 2022 / Accepted: September 4, 2022 / Published: September 6, 2022

List Of Best Laser Hair Removal Treatment In Noida Sector 18

In additive manufacturing (AM), powder properties and laser powder fusion (LPBF) process parameters affect the quality of materials and construction parts. However, the relationship between powder size, LPBF process parameters and mechanical properties is not well established. In addition, Hastelloy X (HKS) attracts attention due to its excellent properties at high temperatures, but it is difficult to process, for example by cutting and grinding, due to its high hardness and high ductility. This can be overcome by using the AM process. We compared the LPBF window process maps for two HKS powders of different sizes. Despite their small difference of 19.7% in particle size, the difference in laser power was confirmed to be greater than 40 V, the difference in scanning speed greater than 100 mm/s, and the difference in energy density greater than 20%. below optimal process conditions. The sample constructed in this way had a larger melt pool size when the energy density was higher, resulting in differences in mechanical properties at room temperature and high temperature (816 °C). We considered controlling the powder size to obtain the properties necessary for each temperature condition. The microstructures and mechanical properties of the thus constructed LPBF samples were also examined and compared with those of cast HKS. Due to the fast melting and solidification process in LPBF, the HKS constructed in this way showed nano-sized dendritic structures and high internal deformation energy. This resulted in the so-constructed LPBF exhibiting higher tensile strength at room temperature than the as-cast material. Under high temperature conditions, the grain boundary of as-built LPBF acts as a sliding track, and LPBF HKS showed significantly better high-temperature tensile strength characteristics than cast HKS.

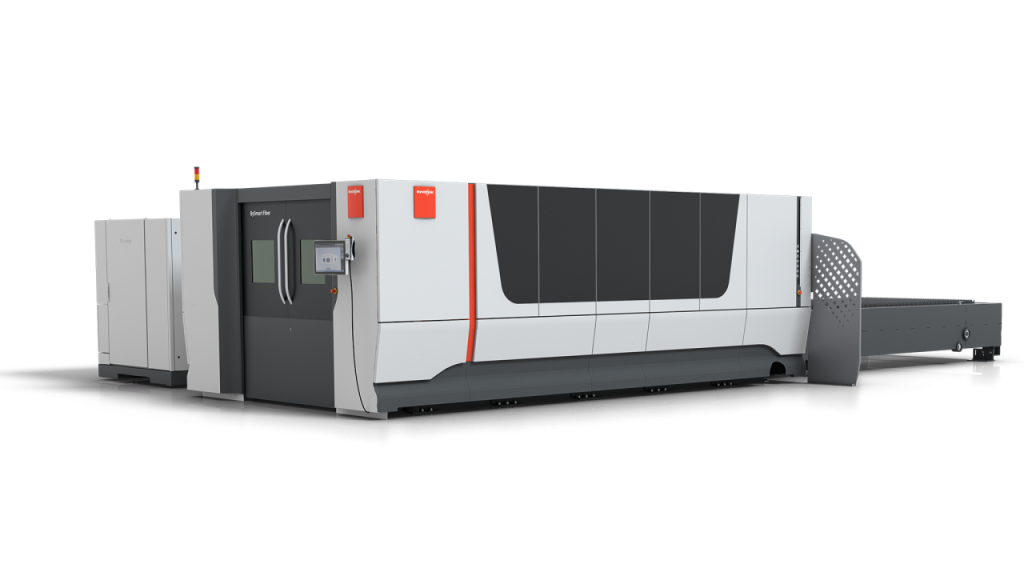

Advances in additive manufacturing (AM) technology have made it an attractive choice for many industries to produce parts that are difficult to produce with conventional casting, plastic and cutting. Laser powder casting (LPBF) is a metal 3D printing process that enables the production of complex and intricate parts (see Figure 1). It is possible to produce different shapes in one base plate at the same time. Therefore, it is very suitable for serial production in small quantities. Due to these process characteristics, various industrial areas have tried LPBF for production [1, 2, 3].

Many attempts have been made to introduce LPBF to the power generation industry, where rapid delivery of large quantities of discontinued parts is essential. Since power plant components are exposed to extremely high temperatures, nickel-based superalloys with excellent high-temperature characteristics are used. Hastelloy X (HKS) is a Ni-Cr-Fe-Mo superalloy with high temperature properties obtained by solid solution or precipitation strengthening. The alloy has excellent resistance to oxidation and air pressure, in addition to its high temperature properties, making it suitable for components used in the aerospace and power generation industries, such as jet engine exhausts and turbine blades [4, 5, 6]. Forged HKS is heavy due to its high hardness. Therefore, it is mainly done with casting. However, in recent years there has been an increasing need to manufacture vital parts using AM.

Since the LPBF process has been widely applied in industry, its process efficiency should be investigated for improvement. This requires high manufacturing volume, dimensional accuracy tolerances allowed by the target part, and excellent surface roughness during part production using LPBF [6, 7, 8]. Parts produced using metal 3D printing have larger internal features and smaller external features as the parts shrink due to the rapid cooling process. The research of S. Giganta et al. [9] shows that the dimensional error caused by these causes is maximized on an inclined surface (especially at 45°), so care should be taken. The LPBF process involves production by melting metal powder with a laser heat source and has many control process parameters [1, 3, 8, 10, 11, 12]. Among them, it was observed that the power of the laser beam and the speed of laser scanning significantly affect the quality and efficiency of the process [7, 10, 13]. In addition, the particle shape, size and composition of the powder material significantly affect the melting through the laser heat source. These factors are directly related to the quality of the material produced by AM. Therefore, it is necessary to choose optimal process conditions by controlling the primary parameters of the LPBF process and powder properties [14, 15, 16, 17, 18]. Due to the importance of process optimization and the difficulty of controlling many variables, recent studies such as the selection of optimal process variables using machine learning [19] and the optimization of properties by post-heat treatment [20] are actively being carried out.

Laser Tissue Interactions: Fundamentals And Applications

The microstructure of materials produced by LPBF and casting is different: unlike casting, the LPBF process only grows as a primary dendrite because the material melts/solidifies quickly, and the secondary dendrite growth time and grain growth time are insufficient. The dendrite is located in the molten pool that is formed when the laser melts the powder [21, 22]. The unique microstructure of these materials produced by LPBF is a factor that affects the physical properties that differ from those of the cast material.

This study analyzes the effect of HKS powder size on the mechanical properties of parts produced by LPBF, in order to select the optimal parameters of the LPBF process. The microstructure and mechanical properties of HKS produced by casting and LPBF were comparatively analyzed. Forty-eight samples were fabricated using two kinds of HKS powders of different sizes and subjected to a laser operating at a scan speed of 120–260 V and 500–1000 mm/s under different conditions. The produced samples are organized as a process window map based on density measurements.

Two types of Hastelloy X powders were selected for this study. The composition of the powder was analyzed by energy dispersive X-ray spectroscopy (EDS) (X-Max 50 mm, HORIBA, Japan), gas chromatography and C/S determinant. FS alloys GH3536 (Powder I) and nickel alloys HKS (Powder II) sputtered, supplied by Farsoon Technologies and EOS GmbH, were chosen because they are widely used in AM technologies. The composition of powder I is 16.1% Cr-16.0%Fe-8.5%Mo-0.7%Co-0.5%V-0.02%Si-0.2%Al-bal. Ni and trace amounts of Ti, Nb, O, N, C and S. The composition of powder II is 22.8% Cr-18.8%Fe-8.6%Mo-1.7%Co-1.0%V-0.1%Si-0.5% Al – ball Ni and amounts Ti, Nb, O, N, C and S in traces. Figure 2 shows that the morphologies of the unused powders are usually spherical. In this experiment, since the microstructures of the AM samples varied with the powder particle size, the particle size distribution of two types of Hastelloy X powders was analyzed using an emission scanning electron microscope (SEM) (SU8020, Hitachi, Japan) and laser granulometry (Mastersizer 3000 unit for wet spraying, Malvern, UK). The results of the analysis showed that the average particle size was D [3, 4], which means that the average value of the powder in the total measurement result, powder I and powder II was 37.1 and 29.8 µm, respectively. That is, powder I showed a larger powder distribution than powder II, as shown in Figure 3 .

Hastelloy X cube samples (10 × 10 × 20 mm) and cylindrical samples (diameter: 12.3 mm, length: 85 mm) were produced with a Farsoon 271 M (Farsoon Technologies, Changsha, China). Samples for tensile testing are made by vertical and horizontal construction. This system used a 500 V Ib fiber laser. Scanning was performed at a base plate temperature of 150 °C in a nitrogen gas atmosphere. The main parameters applied in the LPBF process are:

Lasers In Dermatology And Medicine: Dermatologic Applications

The fabricated and cast samples were medium polished using 320-2000

247 hrms login, apartments 247 login, it’s me 247 login, it’s me 247 online banking login, 247 iris login, car finance 247 login, payday 247 login, money box 247 login, 247 login, fcps 247 blackboard login, 247 finance login, worldclient 247 login